When it comes to aircraft interiors, it’s all in the details. Fast, incomplete work that overlooks details can not only look bad but also compromise the durability of the interior.

Here are 5 ways to know if your upholstery work is a quality job.

#1 French Stitching

What it is: French seams, sometimes called “inverted seams,” are really one seam enclosed within another. The two pieces of material are sewn together with the wrong sides facing each other. The result is two rows of stitching parallel to one another, reinforced raw edges underneath, and a classy detailed finish.

What to look for: Good French stitching will be straight and follow a logical line around the seating. Done right, the stitching should complement the fabric and not draw attention to itself, unless it’s being used as a design feature. There should be no gaps or wrinkling; the fabric should be taut.

The stitching on the left appears to be crooked in spots and does not follow the natural line around the fabric. This draws your attention to the mistake and the fabric wrinkles it has created.

#2 Stress Marks

What they are: During the application process for panels, the material is pulled from the window out. Hasty work can create stress marks, or wrinkled lines, in the corners around the windows.

What to look for: Look all around the edges of the windows and feel with your hands. If you see or feel any ripples, the material was not applied correctly. All of the edges should be smooth and taut, with no wrinkles, gaps, or bagginess.

#3 Bagginess in the Seat Covers

What they are: Bagginess in a seat cover is when the cover does not fit tight over the foam underneath. This can happen for several reasons but primarily because the cover pattern that a shop is using is too loose. Shops will often break apart an old seat cover to create the pattern for the new seat covers. This is faster than making a new pattern from scratch, but – because of wear or a poor original pattern – the new seat cover ends up being too loose.

Another reason why you might end up with a baggy cover is that the stitching has been done incorrectly. The blind stitch (the stitch running through the center of the seat connecting the two fabric pieces) should have 8 stitches per inch. Having fewer stitches can lead to pulls in the fabric over time.

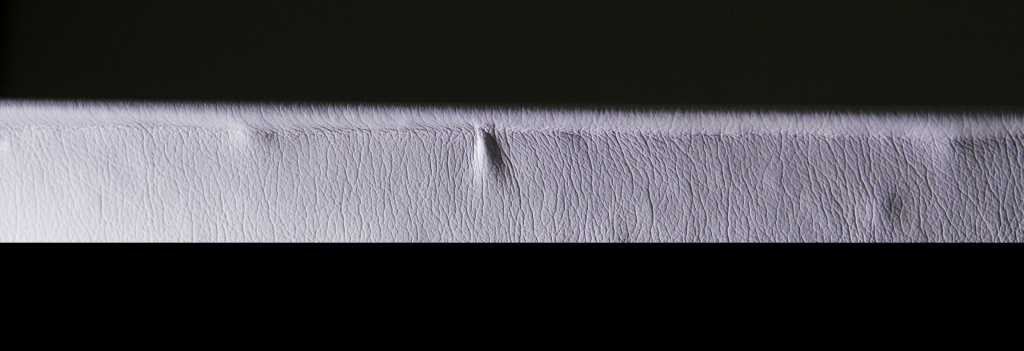

What to look for: Bagginess in the seat cover is easiest to see looking at the seats from an angle with light shining on them. You can also run your fingers across the seat and easily feel them if they are present.

#4 Glue Bumps

What they are: If an adhesive is given too much time to set before the material is applied to a panel, the result is a glob or bump of glue beneath the fabric. These raised imperfections detract from the panel’s smooth finish.

What to look for: Glue bumps are easiest to see when lights are off in the cabin. If there are any issues, you will see shadows created by the glue bumps below. All of the material stretched onto the panels should be smooth and free of waves, bumps, or distortions.

#5 Gaps in Carpeting

What they are: If carpeting is measured incorrectly before installation, there will be gaps between the interior surfaces and the carpet’s raw edge. Besides looking sloppy, this can lead to fraying and rolling.

What to look for: Check all of the carpet’s seams and look for any spacing where the floor beneath is visible. Seams should be against one another, and the carpet’s pattern should continue across seams.

Contact C&L Aviation Group

We are happy to answer your questions. Contact us using the form below, and someone will get back to you as soon as possible.