Looking to simplify and streamline your avionics installations?

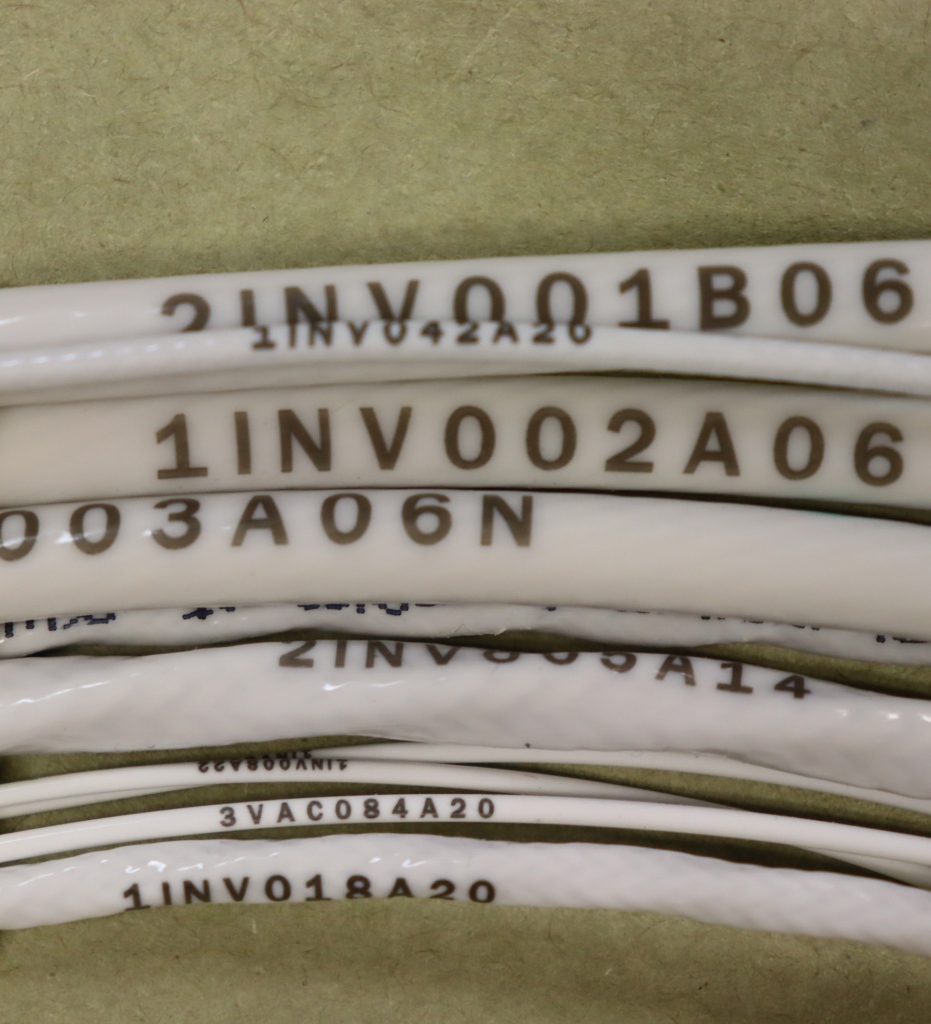

C&L uses nondestructive UV laser-marking technology to custom code various avionics wire types of any length. Laser radiation is absorbed on the surface of the wire insulation with no damage to the wire material inside.

Features of UV Laser-Marking:

- Accommodates 26Ga to 4Ga wire/cable and up to 5/8” shrink tube

- Accommodates round and twisted cables

- Non-destructive, surface marking

- No damage to the internal wire

- High-contrast marking that will not rub off

- OEM approved

- Full graphics capabilities (pictures, logos, barcodes)

- Supports both vertical and horizontal text orientation

- Custom wire harnesses and wire harness fabrication

Features of UV Laser-Marking:

- Accommodates 26Ga to 4Ga wire/cable and up to 5/8” shrink tube

- Accommodates round and twisted cables

- Non-destructive, surface marking

- No damage to the internal wire

- High-contrast marking that will not rub off

- OEM approved

- Full graphics capabilities (pictures, logos, barcodes)

- Supports both vertical and horizontal text orientation

- Custom wire harnesses and wire harness fabrication

Benefits of C&L Aircraft Wiring Service:

- No minimum or maximum order size for continuous lengths

- No spliced wires

- Quick turnaround time with fast, professional shipping

- Easy-to-open and sort packaging

- Bundled and/or sorted into easy-to-organize installation kits

Having your wiring prepared, sorted, and organized ahead of your next aircraft upgrade saves you time and money. (And it’ll save you a ton of frustration during installation!)

Wire Harnesses

In addition to laser wire marking, C&L uses state-of-the-art tools to manufacture high-quality and low-production-run wire harnesses with any number of branches. C&L wire harnesses are designed and engineered to meet specific application requirements for control systems, electrical connectivity, testing, and support on numerous aircraft and equipment platforms.