The carpet on your private jet will wear over time and need to be replaced. Carpet that has worn spots, snags, or stains may negatively affect the perceived value of your aircraft. Regardless of whether you use your corporate jet for private use or charter, or are planning on selling it, replacing the carpet can improve cabin aesthetics, flying experience, and aircraft market value.

Aircraft Carpet Options, Costs, and Lead Time

The following options account for standardized patterns and various levels of customization. The prices are determined by the square yard of material and do not account for installation or labor. Lead times may vary depending on the supplier or level of customization.

Off-the-Shelf Stock: $150-$350 per square yard / approx. 15 business days

If you’re looking to replace your cabin carpeting quickly, you may choose from carpeting readily available in stock. Generally, the interior shop professional will show carpet samples from their suppliers, then order the amount of carpet required.

Semi-Custom Option: $150-$350 per square yard / approx. 15 business days

Semi-custom refers to the process of changing the color in a standard carpet design. For instance, you might want the accent color from your aircraft seats to be incorporated into the carpet pattern. (See “Accent Color” below.)

Note on price and lead time: Price differences between stock carpet and semi-custom design are often negligible, provided the supplier can change the colors in a carpet pattern with colored yarn they already have in stock. The price may increase if the supplier has to custom-dye special colors. The lead time for semi-customized carpet may be a bit longer than for in-stock carpet to account for the process of producing a new carpet.

Custom Option: $350–$5,000 per square yard / 12-18 weeks

Customized carpets may include non-standard pattern designs, specifically-dyed color choices, and any variety of carpet materials (e.g., wool, nylon, polyester, etc.). Logos or branding may be featured as part of the pattern. If you have a favorite rug at home, you might have it replicated for your aircraft.

The sky is the limit when it comes to customized carpet choices, but so is the price tag. Keep in mind that the more customization – and the more unique the materials — the more expensive the carpet. The actual cost and lead time will vary depending on the level of customization.

Aircraft Carpet Styles

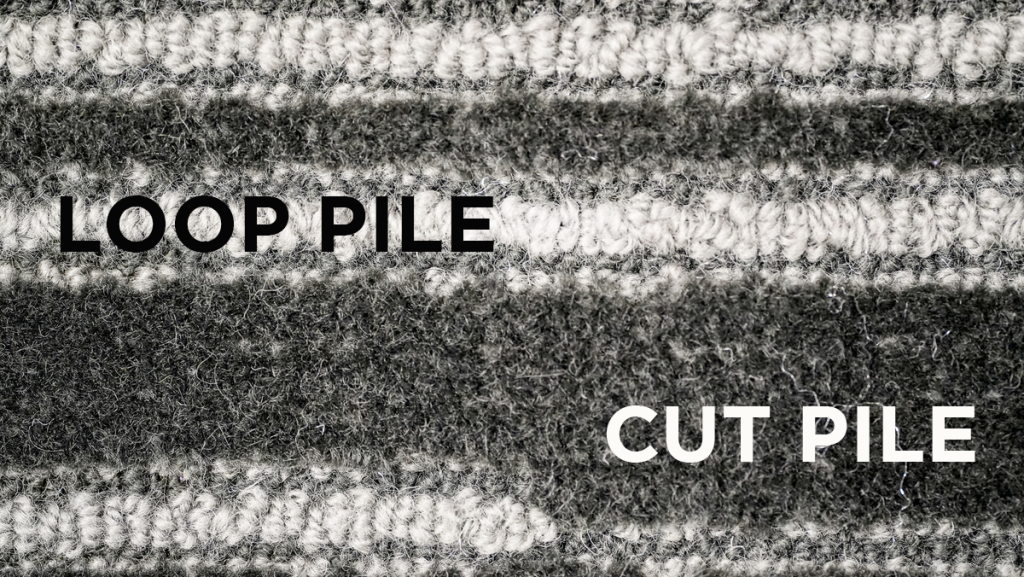

Loop vs Cut

There are three pile styles the carpet can take: loop, cut, and cut & loop. Pile refers to the thickness of the carpet.

Loop pile (a.k.a. “uncut pile”) is a tufted or woven carpet pile surface comprised of uncut loops. Loop pile can be level, textured, or multilevel. A carpet made entirely in the loop style often requires less maintenance than in the cut pile style.

Cut pile starts as a loop pile carpet until the loops are “cut” during the tufting process. This creates a textured look and feel, and the cut pile is softer than loop pile carpets.

Cut pile carpets are easy to clean, though they may require additional maintenance, at least initially. Cut pile carpets will “shed” fibers for up to 6 months and need to be vacuumed after each flight. If not properly vacuumed after each flight, the yarn will start matting, which cannot be repaired. A suction-only vacuum is recommended (a vacuum with a beater bar will propagate more shedding).

Cut & Loop combines both forms. These carpets shed less than cut, making them easier to maintain, and are as durable as loop. Pattern and color combinations are practically limitless.

Serging vs Binding

Two different edge styles help to prevent the edges of your new carpet from fraying: serging and binding.

Serging is when a sturdy yarn is wrapped around the edge of the carpet. The yarn may be the same color as the carpet. Generally, serging is more aesthetically pleasing than binding and is usually sought after for carpets on business jets. However, serged edges are less durable than bound edges because if the yarn wears, it may unravel.

Binding is when a piece of fabric or other material is wrapped around the edge of the carpet. It is generally more durable than serged edges and commonly used on aircraft with more foot traffic, such as charter flights or regional and commercial aircraft. Bound edges are also used in areas where snagging may occur. For instance, if the cabin seats can be moved on a track, the carpet edge alongside the track should be bound to protect the carpet.

Aircraft Carpet Advice

What Carpet Option to Choose Based on Aircraft Use

How the aircraft is used determines what carpet you have installed. For instance, if the aircraft is used for charter flights and sees heavy foot traffic, you may opt for durable and cost-effective carpeting. Carpet that is readily in stock and can be quickly put on an aircraft may be a good choice for charter flights or brokers looking to put the aircraft on the market. For personal use with less wear and tear, more luxurious options could be considered.

When to Get New Carpeting

Cabin carpeting can be replaced at any time, so you do not have to wait for the next time you want to redesign your aircraft interior. This is because carpeting may wear out before other interior components require replacement. Scheduling carpet replacement while the aircraft is in the shop for maintenance or refurbishment helps minimize downtime.

Accent Color

In most cases, you’ll want your carpet to color-coordinate with the rest of your cabin interior. Carpet color is commonly inspired by the colors used on seat leathers, two-tone seats, or window surround panels. Colors may also coordinate with cabinetry and any other cabin features.

Interior shop professionals and designers will work with you to determine color choices and patterns for your aircraft. They may develop digital renderings to help customers visualize the aircraft interior with carpets of certain colors and designs.

Can Carpet Go on the Sidewalls?

The carpet should be on the cabin floor only. While carpeting might go up on humps along the base of the sidewalls, it should not go up the walls of the aircraft. Carpeting on the walls of the cabin is a violation of fire safety.

Carpet Care

The better the carpet is cared for and maintained, the longer it will remain in good condition. Carpets should be vacuumed after every flight, especially if the aircraft is being used for charter. For private use or infrequent flights, the carpet could probably be vacuumed after every other flight.

Steam cleaning is not recommended. If the carpet is unable to dry completely, the cabin may acquire a damp or musty smell.

Detail services may be available at some airports, where you can leave your aircraft while the interior is cleaned.

Extra Carpeting

To protect your carpet, you might have additional mats made from the same carpet pattern that can be placed in areas that receive the most wear, such as the entry and between seats. If your aircraft has an aisle, you might have an extra aisle carpet made so you can use one while the other is being cleaned. Lastly, vinyl maintenance runners can be used to protect the carpet when the aircraft is not in use.