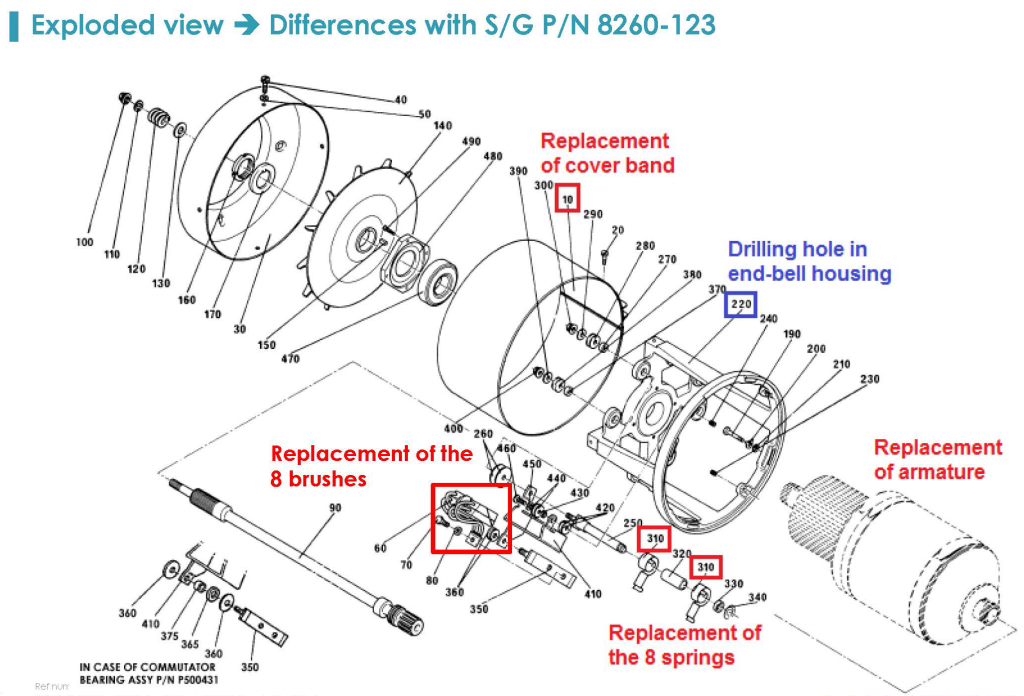

ATR released a new version on the Starter Generator as P/n: 8260-124 with the following technical modifications:

- Higher brushes made from a new material

- A cover with bosses and locating pin

- New commutator technology

- Adapted spring design

The purpose of the modifications was to reduce the direct maintenance costs related to the scheduled maintenance intervals of both the brush and bearing replacements.

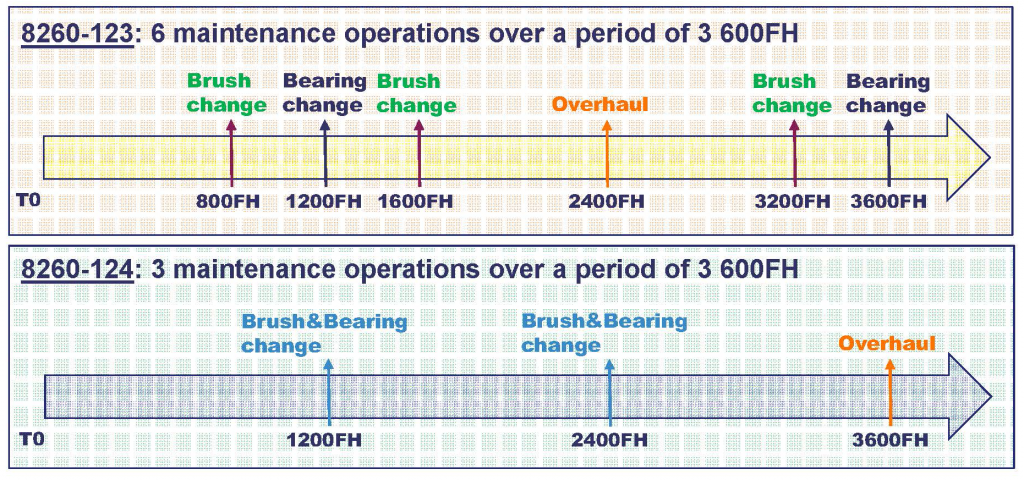

By synchronizing the brush and bearing replacements, the new starter generator achieves longer intervals between removal. The longer intervals between removal mean significant savings for the operator in maintenance costs.

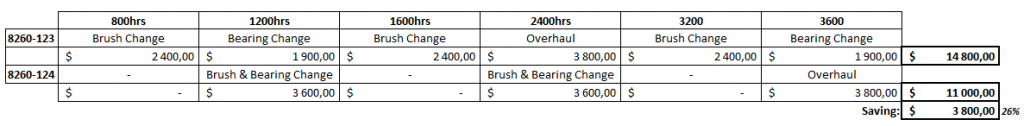

Using the chart above we are able to extrapolate the saving in shop costs.

As you can see from the scheduled maintenance chart above, the new starter generator results in a 26% decrease in shop costs over the course of 3600 hours.

Additionally, this is the saving on just one starter generator and as each ATR has two of these generators the savings is doubled. The starter generator is the same across all ATR aircraft so any ATR operator can take advantage of this cost savings.

ATR72’s from MSN 1238 already have the 8260-124 installed, ATR42’s from MSN 1201 already have the 8260-124 installed.

On the ATR72 & the ATR42-500/-600, there is a modification to be made on the fuel drainpipe on each engine to accommodate the new generator. This is done via a service bulletin (SB) from ATR. There is no cost for the SB from ATR and all operators have access to the SB which would reflect their MSN.

There is a cost for the kit required, unfortunately. One kit covers both sides of the aircraft as it consists of two pipes and two unions. SB’s are attached. C&L can supply the kit for the operator, or the operator could source the kit directly from ATR.