You may not need aircraft brakes to take off, but you certainly can’t take off without them. The ATR 72 has recently posed challenges for operators in acquiring adequate carbon brakes. Options for ATR 72 brakes are limited and expensive – and the only choice if you want your ATR 72 to be airworthy.

What made these aircraft brakes so difficult to obtain and so pricey? What are the available options for replacing or converting your ATR 72 carbon brakes? As experts in ATR services, repair, and aircraft parts, we can help you answer these questions and make the right decision for your operations.

Why Are There So Few ATR 72 Carbon Brakes?

ATR 72 aircraft relied on carbon brakes originally manufactured by Dunlop Aviation until Meggitt bought Dunlop and later discontinued the carbon heat stacks for the Dunlop brakes. Meggitt and Safran have developed alternative carbon brakes and are now the only companies offering carbon brakes approved for ATR 72 aircraft.

If your ATR 72 still has Dunlop brakes, conversions to either Meggitt or Safran brakes require the replacement of both the brakes and the main wheels. Aircraft brakes have a specific keyway into which the wheels fit, making them incompatible with other brands. This can make conversions from Dunlop aircraft brakes expensive.

Obtaining partially used brakes on the resale market offers a more cost effective option, but these aircraft brakes are becoming more scarce.

When Will This Become a Problem?

The ATR 72 carbon brake issue is a problem now. ATR published a retrofit information letter in 2017, announcing the conversion to the new Meggitt or Safran brake as the solution to the obsolete Dunlop brake.

What could have been a gradual phasing into the new brake was significantly accelerated due to the COVID-19 pandemic. The ATR 72 became a popular choice for freight because it could be converted quickly and cheaply for cargo. When regional air service resumed, the ATR 72 was also one of the aircraft commonly used for passenger flights. The increased use of the ATR 72 resulted in high usage of the brakes, speeding up the need for replacements.

Whom Will It Affect?

Any operator flying ATR 72 aircraft with older Dunlop brakes will have to switch to either Meggitt or Safran brakes in the near future. If you are leasing an ATR aircraft, check your contract with the aircraft owner to determine whether you or the owner is responsible for upgrading the brakes.

What are the Available Options for ATR 72 Carbon Brakes?

Conversion of Dunlop Brakes to Meggitt Brakes

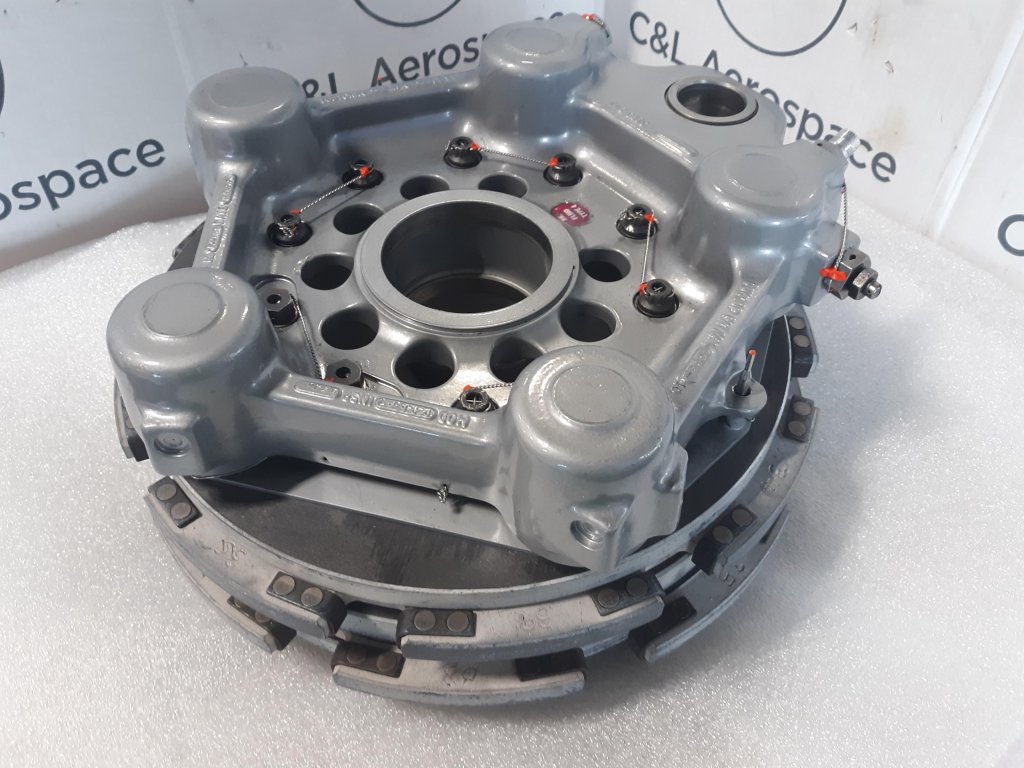

Meggitt works with the ATR Original Equipment Manufacturer (OEM). The first of two options available through Meggitt is a modification kit used to convert Dunlop main wheels and brakes to Meggitt (P/N 90010199), in accordance with a Meggitt Service Bulletin. (Different Dunlop brake types require either a partial or full conversion.)

Replacement with the New Meggitt Brakes

The second option available through Meggitt and via an ATR Service Bulletin is to completely replace the existing Dunlop main wheels and brakes with the new Meggitt wheels and brakes. Improvements have been made to the Meggitt brake (P/N 90010199) over the Dunlop brake. These improvements include a new brake housing axle, a stronger heat stack using their NuCarb® carbon material, and a one-piece torque tube.

Conversion of Dunlop Aviation Brakes to Safran Landing Systems

Safran offers the only alternate for the Dunlop/Meggitt ATR 72 brakes. Safran’s wheels (P/N C20586120) and brakes (P/N C20585712) are comparable to Meggitt’s in quality, performance, and price. Choosing one supplier over the other will be based on the availability of parts, the operator’s preference, and convenience. For instance, if the operator uses Safran for one of their aircraft, they may choose to have the same supplier for the rest of their fleet.

Should You Invest in New ATR 72 Carbon Brakes?

Replacing your existing brakes and main wheels with either Meggitt or Safran can range in price from $165,000 to $190,000. This price range does not account for the cost of labor and downtime.

Consider the following questions before committing to the expense.

How many more years will the aircraft be in use?

Investing in new brakes may not be worth the cost if you plan on retiring your ATR 72 aircraft soon. You would need to have the aircraft for a minimum of 3 years (approximately 2,000 landings) to receive a return on your investment.

Are there ATR carbon brakes available through teardown or resell?

Sometimes brakes are removed from ATR aircraft that still have some life remaining and sold. This often results from teardowns or because the operators have spares they no longer need. Although this option may be less costly than purchasing new aircraft brakes, it is only a temporary solution. This is a good option for operators who plan to retire their ATR 72 aircraft in the near future.

Do you have spare brakes on hand?

Carbon brakes can wear at different rates. For instance, one brake may need to be replaced while the other brakes still have some life remaining. If all brakes were replaced with one of the new options, the removed brakes that are still usable could be used as spares. Alternatively, they could be sold to help pay for the new brakes.

Are you looking to purchase or lease an ATR 72 Aircraft?

If you want to purchase or lease an ATR 72 for your operation, you should first identify what brakes are on the aircraft. If the aircraft requires one of the new options of wheels and brakes, the aircraft price should reflect this. Alternatively, you may have an agreement in place to cover the pending modification.

How to Prolong the Life of Your Current ATR 72 Carbon Brakes?

The most wear on your carbon brakes (79%) occurs during taxi out as opposed to landings (19%) and taxi in (2%), according to Aircraft Braking Systems (ABS) Corporation. Wear on brakes decreases when brakes are warmer (after being in operation). To prolong the life of your brakes, some operating procedures can be performed during taxiing and landings.

- Avoid riding the brakes

- Perform taxi-out stop events at a higher speed

- Reduce the number of taxi-out stop events

- Use negative propellor pitch and the full length of the runway for landing

While these procedures will help extend the life of your aircraft brakes, they will still need to be upgraded before the carbon wears down to unsafe levels (approximately 3-5%). Plan ahead for investing in new brakes and involve your organization’s finance department to budget for the upgrade.

Remember, whatever goes up must come down, and you want reliable aircraft brakes when your ATR 72 touches the ground.