One of the most common issues on the Hawker 800 Series is skin corrosion on the leading edges. Skin corrosion may not be visible initially, which could make it difficult to identify.

What can you do to protect your Hawker leading edges against corrosion, and what are the available solutions if corrosion is discovered? This article explains how to minimize Hawker leading edge corrosion and how to appropriately handle corrosion if it is identified on your aircraft.

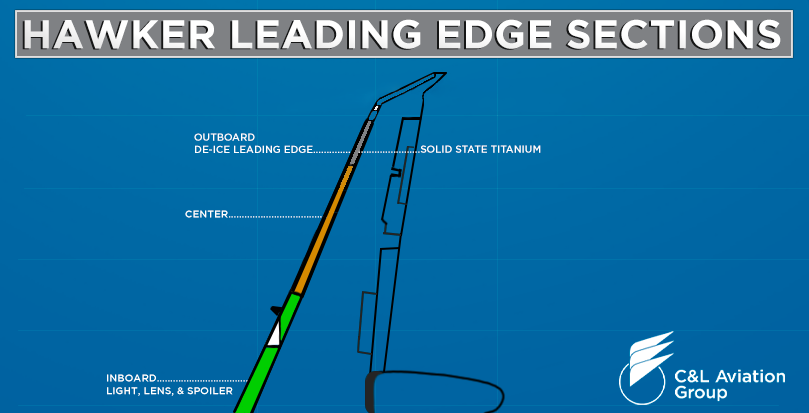

What Are Hawker Leading Edges and De-Ice Panels?

The Hawker leading edges are the forward portion of an airfoil. They are the first surface to make contact with the air. On the Hawker aircraft, de-ice panels are fitted over the structural leading edge sections. The de-ice panels are part of an ice protection system, sometimes known as weeping wing technology, that releases an ethylene glycol-based fluid over the wing and creates a film to which ice cannot adhere.

The space where the de-ice panels fit over the leading edge is the “rebate” area. A sealant is applied in the gap where the de-ice panels and leading edges meet to avoid moisture ingress.

The leading edge consists of three structural sections: inboard (which includes a light, lens, and spoiler), center, and outboard (solid-state, titanium). Only the inboard and center sections have separate de-ice panels. The outboard titanium section integrates the de-ice function within the leading edge structure.

How to Find Corrosion Issues on Hawker Leading Edges?

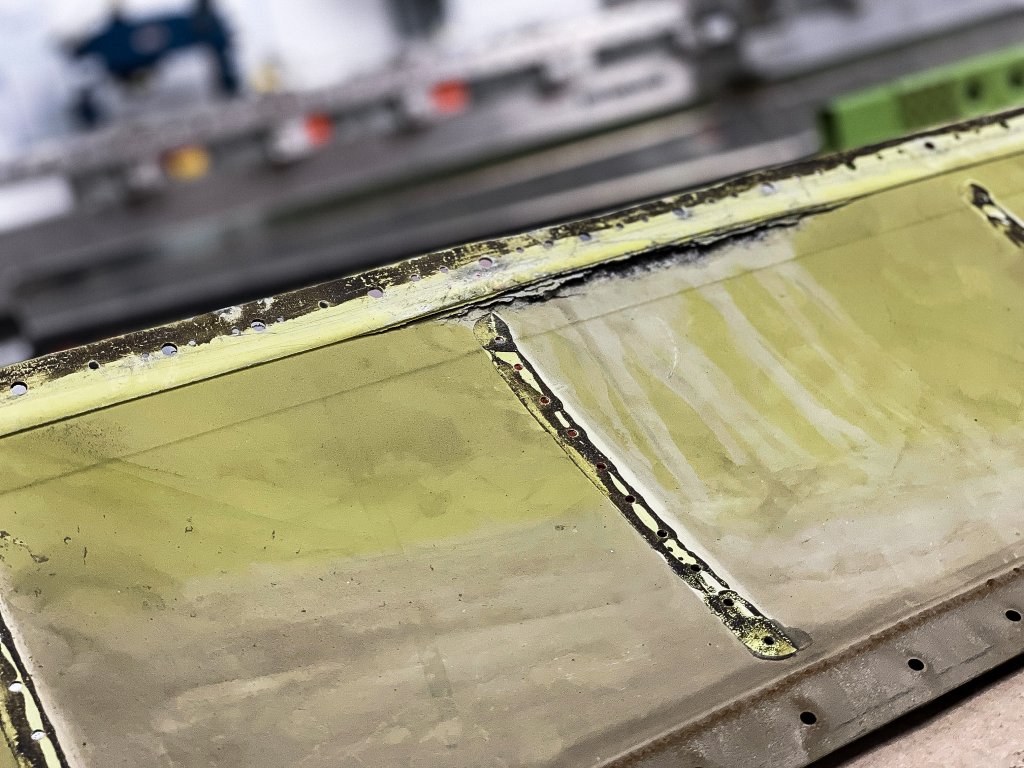

Generally, corrosion issues are found during maintenance inspections (e.g., 48-month check, etc.) when de-ice panels and sealants are removed. In most cases, you won’t have to dismantle your aircraft’s wing outside of an inspection. However, if you do need to remove the de-ice panels, it is recommended that you take the opportunity to thoroughly inspect the leading edge. If corrosion is identified early enough, it can be rectified at that time to avoid future leading edge replacement skins. Corrosion left untreated will only get worse.

How to Prevent Corrosion on Hawker Leading Edges?

Moisture ingress from leaking de-ice fluid is a leading cause of corrosion on leading edges. Regularly testing the installed de-ice panels determines whether the fluid disperses properly over the wing. Fluid that does not properly coat the wing may be seeping somewhere else. Such areas include either between the de-ice panel and the leading edge skin or behind the skin and into the structure of the leading edge.

Another cause of corrosion on leading edges is moisture ingress from the elements. Corrosion results from an aircraft being stored outside of a hangar or operating in an environment with more precipitation. If the sealant has worn away and moisture enters the leading edge’s rebate area, the de-ice panels may delaminate and corrode. Ensuring that the sealant is properly maintained and replaced when needed can help prevent corrosion. Routine polishing of the leading edges also helps prevent corrosion and promotes the overall health of the skin.

For further protection, Teflon® tape and paint are used to create a moisture barrier. They are added to the rebate area during leading edge overhaul.

How to Repair Corrosion on Hawker Leading Edges?

If there is minimal corrosion on the Hawker leading edge, it may be repairable through a process called “blending.” The corroded area is ground down to the unblemished metal.

Some corrosion is permittable. The corrosion-damaged area must be within the limits specified in the structural repair manual (SRM), which is not to exceed a total length of 12 inches on the upper and lower rebate areas.

What to Know About Overhauling Hawker Leading Edges?

If corrosion exceeds the allowable limits, the leading edge will need to be overhauled and the skins replaced.

Overhaul Lead Time

Leading edge overhauls take approximately 30 days, depending on the shop’s current workload, capabilities, and availability of piece parts.

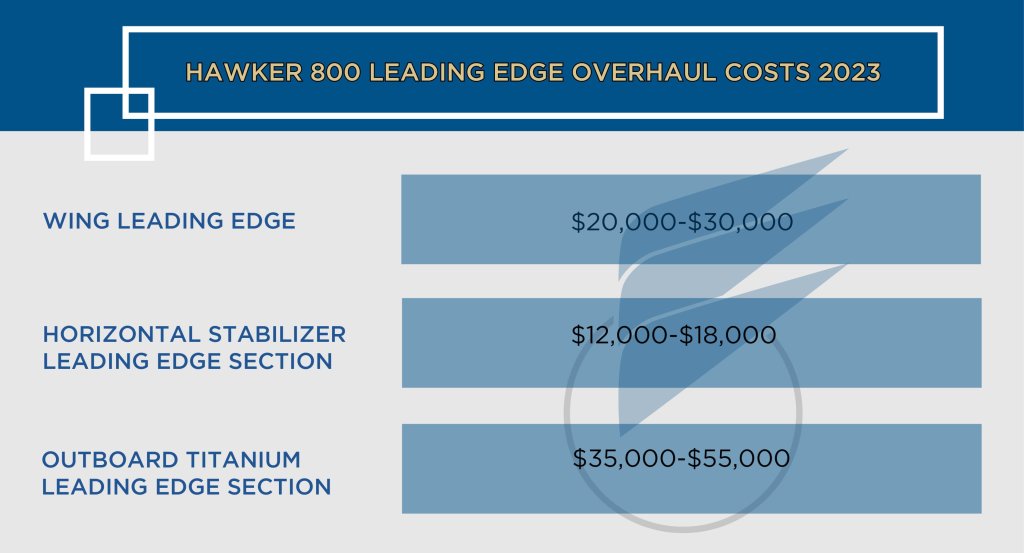

Overhaul Cost

Costs vary based on the section of the leading edge being overhauled.

- $20,000-$30,000 per wing leading edge section

- $12,000-$18,000 per horizontal stabilizer leading edge section.

- $35,000-$55,000 per outboard titanium leading edge section.

How to Exchange Hawker Leading Edges?

If you do not have time to wait for your Hawker leading edge to be overhauled, you may be able to exchange the leading edge.

Be cautious of leading edges on the market in As Removed (AR) or removed serviceable conditions. Leading edges in these conditions may have existing corrosion or other issues.

Flat Rate Exchange

With an exchange, you’ll receive ready-to-install leading edges from the supplier. You will then need to ship your off-unit to the supplier. Your off-unit will need to be repaired or overhauled, and you may be charged the repair or overhaul costs. If you ship your off-unit to the overhaul shop in advance, you may be able to determine the level of corrosion and costs associated with overhauling the unit. The supplier should then be able to provide a true flat rate exchange where you pay one price with no additional billings.

How to Avoid Hawker Leading Edge Fitment Issues?

Although leading edges and de-ice panels have a standardized shape, there can be some variance between aircraft. This may affect how well the leading edges and de-ice panels fit together. Generally, variations are slight and can be easily corrected through minor adjustments, known as shimming.

Fitment issues (and any over and above (O&A) costs) can be avoided by providing your supplier or overhaul vendor with all the necessary components in advance. This usually includes the leading edge and de-ice panels. The light and lens should also be sent if the inboard sections are being overhauled. This allows the supplier or vendor to dry-fit all components together to ensure that they fit correctly before returning the components for installation on the aircraft.

What Happens If Corrosion Issues Are Not Addressed?

Corrosion issues don’t go away; they get worse. Corrosion can spread throughout the leading edge, potentially affecting the interior ribs. Not having corrosion issues resolved in a timely manner can result in more in-depth maintenance and delay the release of the aircraft back to service, thus prolonging downtime and increasing costs.

How Does C&L Address Corrosion on Hawker Leading Edges?

If you would like to learn more, check out this video where we demonstrate our process for addressing corrosion on Hawker leading edges. If you have any questions about how to protect your Hawker’s leading edges against corrosion, please fill out the contact form below.